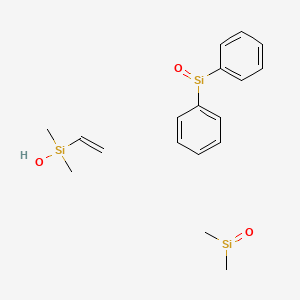

Vinyl-terminated Polysiloxanes di-Me, di-Ph

- CAS No. :68951-96-2

- Molecular Formula:C18H26O3Si3

- Purity:

- Molecular Weight:374.7g/mol

Product Details

Chinese factory supply Vinyl-terminated Polysiloxanes di-Me, di-Ph 68951-96-2 in stock with high standard

Vinyl-terminated Polysiloxanes di-Me, di-Ph

CAS No. 68951-96-2

Appearance: Clear yellowish to colorless liquid

Vinyl terminated polydimethylsiloxane dimethyl diphenyl is a type of polydimethylsiloxane containing vinyl functional groups at the end of its molecular chain, with dimethyl and diphenyl side chains. This material has good reactivity and thermal stability, and is commonly used in the preparation of high-performance silicone rubber and sealants.

Vinyl-terminated Polysiloxanes di-Me, di-Ph 68951-96-2 Factory

Producing vinyl-terminated polydimethylsiloxane (PDMS) or vinyl-terminated polysiloxanes involves a few steps in a controlled synthesis environment, generally carried out via hydrosilylation or equilibrating polymerization methods. Wuhan Kemi-Works Chemical Co., Ltd. is specialized in the R&D, production and sale of Special fine chemicals organic silicone chemicals, organic fluoro chemicals, Fluorosilicone chemicals, electroplating chemicals, OLED intermediates and chemical indicators. Widely used in pharmaceutical, pesticide, OLED, electronics, electroplating, organic synthesis and other fields. Our business mainly focus on the conventional products, complemented by custom chemical production, we can accept the client's request, providing services such as structural analysis, research synthesis route and standard samples. We have set up R&D center, quality inspection center and manufacturing site in Hubei and Zhejiang. We have professional sales team, focus on quality and service, and we have achieved excellent performance over the years. Our company is committed to the development of international markets , our products are mainly exported to many countries and regions, such as Europe, America, South-east Asia, the Middle East and Africa etc.

1. Vinyl-Terminated Polydimethylsiloxane (di-Me)

Molecular Structure: ( 𝐶 𝐻 3 ) 2 𝑆 𝑖 𝑂 (CH 3 ) 2 SiO backbone with vinyl-terminated ends.

Appearance: Clear, viscous liquid (low to medium molecular weight) or soft solid (higher molecular weights).

Thermal Stability: Good thermal stability, withstanding temperatures up to 200°C to 250°C. Can degrade or lose properties above this temperature.

Glass Transition Temperature (Tg): Typically very low, around -120°C, allowing flexibility at low temperatures.

Viscosity: Ranges from low to very high, depending on the molecular weight. Vinyl termination allows tunability for specific applications, such as coatings or elastomers.

Surface Tension: Low surface energy, providing excellent release and hydrophobic properties.

Chemical Resistance: Highly resistant to most chemicals and solvents, though it can swell in nonpolar solvents like hexane.

Mechanical Properties: Exhibits high elasticity, flexibility, and low modulus, making it ideal for applications where elongation and flexibility are important.

2. Vinyl-Terminated Polydiphenylsiloxane (di-Ph)

Molecular Structure: ( 𝐶 6 𝐻 5 ) 2 𝑆 𝑖 𝑂 (C 6 H 5 ) 2 SiO backbone with vinyl end groups.

Appearance: Clear to slightly amber viscous liquid or gel, depending on molecular weight.

Thermal Stability: Improved thermal stability compared to di-Me, with resistance up to 300°C, making it suitable for high-temperature applications.

Glass Transition Temperature (Tg): Higher than di-Me, around -60°C to -80°C, providing good low-temperature flexibility with enhanced mechanical strength at elevated temperatures.

Viscosity: Tends to be higher than di-Me for similar molecular weights due to phenyl substitution, which increases intermolecular interactions.

Surface Tension: Slightly higher than di-Me, but still low relative to other polymers, maintaining good release properties and hydrophobicity.

Chemical Resistance: Enhanced resistance to nonpolar solvents and aromatic hydrocarbons due to the phenyl groups, making it more suitable for harsh chemical environments.

Mechanical Properties: Higher tensile strength and stiffness than di-Me, with moderate flexibility and excellent dielectric properties, which can be beneficial in electronics and high-performance coatings.